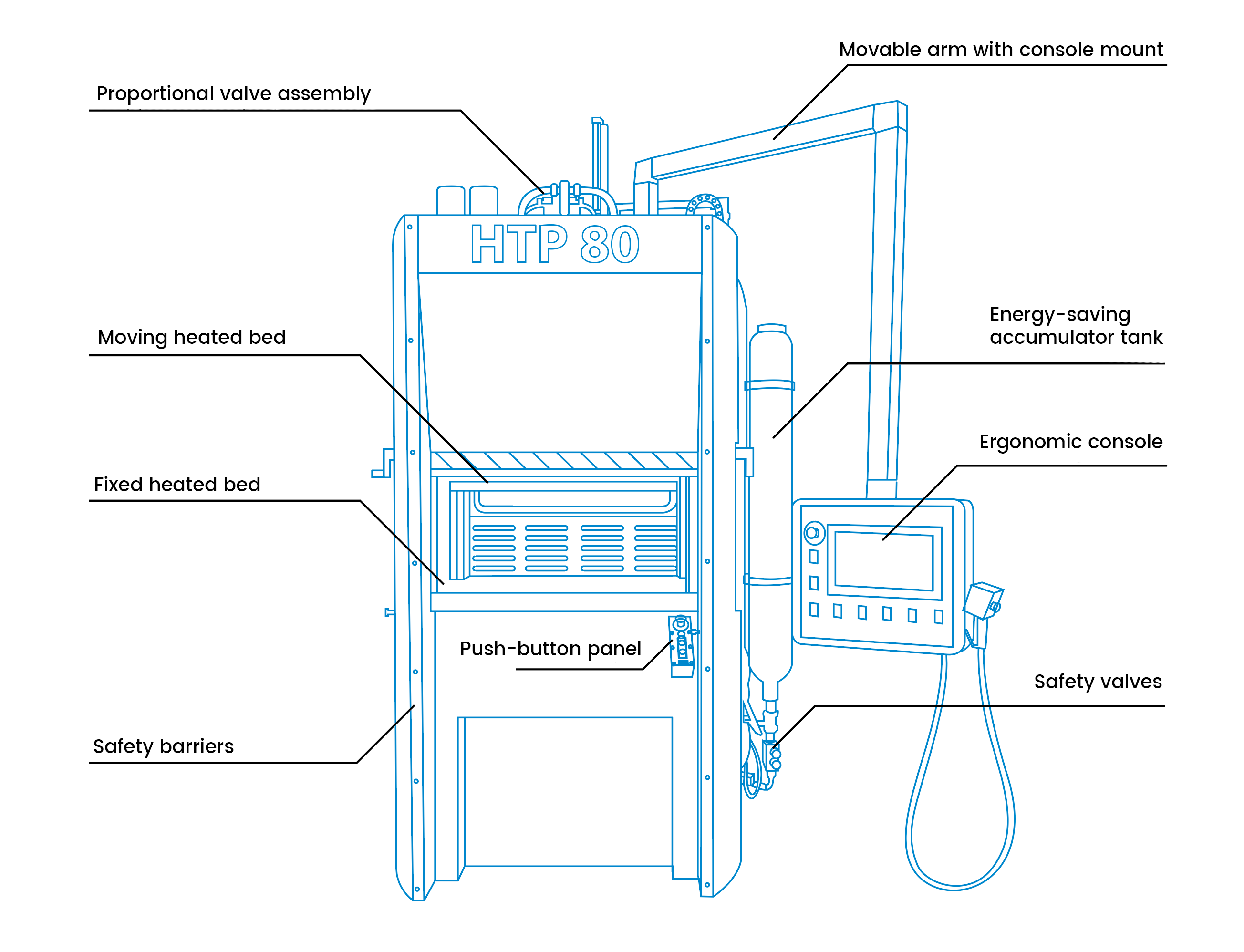

Our new HTP high-performance press machine was entirely designed and manufactured by our company: its technical features are patented by Comaut.

This unique thermoforming machine can operate with 3D moulds as well and stands out among the competitors by serializing two separate steps: the ordinary thermoforming process is followed by an absolutely precise die-cutting of products.

Speed and accuracy are the winning features of our machine, which can provide a force of 80 tonnes with outstanding precision.

By assuming full control of multiple functions, HTP machines allow for thermoforming, die-cutting, and shearing more different products at the same time. HTP machines can control multiple variables at once in order to manufacture more diverse products with the utmost precision:

• Press closing time

• Ascending and descending speed

• Different area temperatures for each product

• Several power adjustment settings

HTP machines employ IoT technology for constant, accurate remote monitoring, as all other new Comaut machinery do. The efficiency degree, performance, and progress are displayed through a specific software which reports any issues or malfunctions as well, thus allowing prompt and effective actions to be taken. Moreover, HTP machines allow customers to benefit from Industry 4.0 tax incentives.

• Load capacity: 80ton

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/6 controllers: 3 upper and 3 lower controllers)

• Mould opening stroke: max. 400mm

• 3-step bed descent speed: 150mm/s in fast descent mode, 10mm/s when slowing down, 2mm/s during approach

• Automated forming and die-cutting

• Press control by position and pressure transducers (descending only)

• 2 pistons for a more uniform pressure distribution

• PLC control system

• Specific software for handling remote orders

• Cool-down system with integrated chiller

• Benefits from Industry 4.0 hyper-depreciation

• Load capacity: 80ton

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/6 controllers: 3 upper and 3 lower controllers)

• Mould opening stroke: max. 400mm

• 3-step bed descent speed: 150mm/s in fast descent mode, 10mm/s when slowing down, 2mm/s during approach

• Automated forming and die-cutting

• Press control by position and pressure transducers (w/2 types of transducers: ascending and descending)

• Hydraulic accumulator

• 2 pistons for a more uniform pressure distribution

• PLC control system

• Specific software for handling remote orders

• Cool-down system with integrated chiller and submersible pump to reduce noise

• Benefits from Industry 4.0 hyper-depreciation

• Load capacity: 50ton

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/6 controllers: 3 upper and 3 lower controllers)

• Mould opening stroke: max. 500mm

• 3-step bed descent speed: 120mm/s in fast descent mode, 10mm/s when slowing down, 2mm/s during approach

• Automated forming and die-cutting

• Press control by position and pressure transducers (descending only)

• Hydraulic accumulator

• 2 pistons for a more uniform pressure distribution

• PLC control system

• Specific software for handling remote orders

• Cool-down system with integrated chiller

• Benefits from Industry 4.0 hyper-depreciation

• Load capacity: 50ton

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/6 controllers: 3 upper and 3 lower controllers)

• Mould opening stroke: max. 500mm

• 3-step bed descent speed: 120mm/s in fast descent mode, 10mm/s when slowing down, 2mm/s during approach

• Automated forming and die-cutting

• Press control by position and pressure transducers (descending only)

• 2 pistons for a more uniform pressure distribution

• Servo-pump operation

• PLC control system

• Specific software for handling remote orders

• Cool-down system with integrated chiller

• Benefits from Industry 4.0 hyper-depreciation

• Load capacity: 30ton

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/6 controllers: 3 upper and 3 lower controllers)

• Mould opening stroke: max. 400mm

• 3-step bed descent speed: 100mm/s in fast descent mode, 10mm/s when slowing down, 2mm/s during approach

• Automated forming and die-cutting

• Press control by position and pressure transducers

• 2 pistons for a more uniform pressure distribution

• PLC control system

• Specific software for handling remote orders

• Cool-down system with integrated chiller

• Benefits from Industry 4.0 hyper-depreciation

• Load capacity: 12ton

• Thermoforming-only press machine

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/2 controllers: 1 upper and 1 lower controller)

• Mould opening stroke: max. 400mm

• 2-step bed descent speed: 100mm/s in fast descent mode, 2mm/s when positioning

• Press control by position and pressure transducers

• 2 pistons for a more uniform pressure distribution

• PLC control system

• Control panel with air or oil cooling system

• Load capacity: 3ton

• Thermoforming-only press machine

• Pneumatic press machine

• Workbench size: max. 1000x550mm

• Heated beds at max. 220°C

• Heated bed temperature control (w/2 controllers: 1 upper and 1 lower controller)

• Mould opening stroke: max. 500mm

• Fixed, 1-step bed descent speed: 120mm/s

Extra accessories provided on customer’s request